03 Wombat oiler issues - different advice from the tech guys

03 Wombat oiler issues - different advice from the tech guys

Dang it..... just wrote a masterpiece and then hit submit and it directed me to log-in again. Lost it all. So, now the quick version: Thought my crank seals had gone due to massive oil/smoke emitting from the exhaust. Changed seals and rings while I was there..... fired up with some pre-mis in the tank to carry me over until the prime on the oiler was working. The oiler line ot the case was working and within minutes I had the smoke issue AGAIN. Started to realize that maybe my crank seals never were the issue. Disconnect the oiler tube to the case (The carb/intake oiler tube has yet to suck or push oil out yet). After to many kicks it starts and smokes and then slowly starts to get better with it eventually being fine. ok.... I know my issue.

Call Paul and Paul suggests I chuck the oiler but that I need to drill a hole to allow mix to a bearing. Start asking other questions about the oiler and Paul recommends that I call one of the tech guys. Now.... keep in mind. I love these guys. I have called probably each and every one and they have been nothing but kind, informative and genuinely interested in what your doing. My hat is off to them all. Now, after taking with one of them... who has been doing this for over 50 years, he tells to to chuck the oiler but was not aware that ANY hole needed to be drilled. He has ran many bikes like that with never an issue. Now after pulling the engine, breaking the cases, I'm not interested in doing that again and drilling something if I don't have to. I would love to hear any and all comments. Please note, this is not a he said, he said..... I recognize these guys are all professionals and value each and every one's opinions.

Dave

Call Paul and Paul suggests I chuck the oiler but that I need to drill a hole to allow mix to a bearing. Start asking other questions about the oiler and Paul recommends that I call one of the tech guys. Now.... keep in mind. I love these guys. I have called probably each and every one and they have been nothing but kind, informative and genuinely interested in what your doing. My hat is off to them all. Now, after taking with one of them... who has been doing this for over 50 years, he tells to to chuck the oiler but was not aware that ANY hole needed to be drilled. He has ran many bikes like that with never an issue. Now after pulling the engine, breaking the cases, I'm not interested in doing that again and drilling something if I don't have to. I would love to hear any and all comments. Please note, this is not a he said, he said..... I recognize these guys are all professionals and value each and every one's opinions.

Dave

Re: 03 Wombat oiler issues - different advice from the tech

The only model engine I AM AWARE OF that needs the hole drilled is the 03 Wombat. You can strip the motor and send the case to someone like Ron Liddle (I use him, great guy) or do it yourself. If you are unsure of how to do this, send it out before you seize the engine bearing.

Re: 03 Wombat oiler issues - different advice from the tech

Yes Dave has an 03 Wombat that was why I suggested having the hole drilled to feed the left main bearing instead of the oil pump.

Dave did you tell the Hodaka mechanic you mentioned who was not aware of any hole that needed to be drilled that you have an 03 Wombat?

If you do not use the oil pump or do not drill that hole there is no lubrication going to the left main bearing. Might last a while but not to long I would think.

Thanks

Paul

Dave did you tell the Hodaka mechanic you mentioned who was not aware of any hole that needed to be drilled that you have an 03 Wombat?

If you do not use the oil pump or do not drill that hole there is no lubrication going to the left main bearing. Might last a while but not to long I would think.

Thanks

Paul

Re: 03 Wombat oiler issues - different advice from the tech

Paul, yes I told him it was an 03 Wombat. Without saying any names although it's probably not a big deal, he's from Oklahoma. He did mention his last was a road toad and it sounds like the 03 Wombat is different. So, a couple of questions. Can I drill this with the engine still in the bike with the cylinder off? I can get my commercial mini vac (Small and very efficient) in there and clean out any filings. Are there any instructions on this? Sending out an engine is costly and not something I really have time to do. On the other side of the coin. Why is my oiler putting so much oil into the case. Let's re-examine my original question. Do the oiler tubes (one to the carb/intake and the other to the case) have different output's of oil? Is there a possibility that I have them backwards?

Re: 03 Wombat oiler issues - different advice from the tech

BTW.... I did take of of the other tech guys suggestion and make sure the oiler was not turning on to quickly. Told him I had matched the notches perfectly. Not to sure what else to do there. And for the life of me I cannot find ANY documentation on these oilers. Any ideas?

Dave

Dave

- socalhodaka

- Posts: 927

- Joined: Fri Jul 19, 2013 10:31 am

Re: 03 Wombat oiler issues - different advice from the tech

I had a bad seal on a Yamaha I have and it took quite a while to burn all the oil out of the crank case.

- Bullfrog

- Posts: 2796

- Joined: Mon Jul 22, 2013 4:05 pm

- Location: Oregon, 12 miles from the center of the Hodaka Universe(Athena)

Re: 03 Wombat oiler issues - different advice from the tech

Semi-helpful reply coming as soon as I can squeeze in a bit of time with my scanner and the Wombat 03 Owner's Manual.

Bye for now,

Ed

Bye for now,

Ed

Keep the rubber side down!

Re: 03 Wombat oiler issues - different advice from the tech

Hey Dave,

The 03 is one of my favorite Hodaka's and I have a lot experience with that engine. I have to wonder if one of the check valves at the end of the oil lines is working properly....there are two of them on this engine. The check valve contains a one way valve that might be stuck in the open position and that might cause the problem you are describing. The check valve has a spring with a ball that controls direction of flow. You would have to remove the check valve from the carb manifold and the crankcase to inspect. Look inside the check valve from the hose connection end and you should see the small check ball. Next put a short clean piece of hose on the end of the check valve, put the loose end of the hose in your mouth and blow. If there is no resistance the valve is stuck open. I do not remember if I could unseat the valve that way but it is a good quick way to see if the vavle is stuck open.

As for drilling the lube hole with out dis-assembling the engine... I personaly can not think of any way you could drill that hole satisfactorily with the engine assembled. Drilling the hole at the proper angle to intersect the space between the left bearing and crank seal would be problem #1. Keeping the metal chips out of the engine would be problem #2. The potential to damage the crankshaft bearing and seal surface would be problem #3. I usually perform that modification to the left crankcase half in my drill press....with the engine dis-assembled of course.

The check valves need to be inspected and then oil volume out put can be tested. As it is getting late I will get that info for you shortly.

Danny Cooke

The 03 is one of my favorite Hodaka's and I have a lot experience with that engine. I have to wonder if one of the check valves at the end of the oil lines is working properly....there are two of them on this engine. The check valve contains a one way valve that might be stuck in the open position and that might cause the problem you are describing. The check valve has a spring with a ball that controls direction of flow. You would have to remove the check valve from the carb manifold and the crankcase to inspect. Look inside the check valve from the hose connection end and you should see the small check ball. Next put a short clean piece of hose on the end of the check valve, put the loose end of the hose in your mouth and blow. If there is no resistance the valve is stuck open. I do not remember if I could unseat the valve that way but it is a good quick way to see if the vavle is stuck open.

As for drilling the lube hole with out dis-assembling the engine... I personaly can not think of any way you could drill that hole satisfactorily with the engine assembled. Drilling the hole at the proper angle to intersect the space between the left bearing and crank seal would be problem #1. Keeping the metal chips out of the engine would be problem #2. The potential to damage the crankshaft bearing and seal surface would be problem #3. I usually perform that modification to the left crankcase half in my drill press....with the engine dis-assembled of course.

The check valves need to be inspected and then oil volume out put can be tested. As it is getting late I will get that info for you shortly.

Danny Cooke

- Bullfrog

- Posts: 2796

- Joined: Mon Jul 22, 2013 4:05 pm

- Location: Oregon, 12 miles from the center of the Hodaka Universe(Athena)

Re: 03 Wombat oiler issues - different advice from the tech

Hot dang that was a good post Danny!

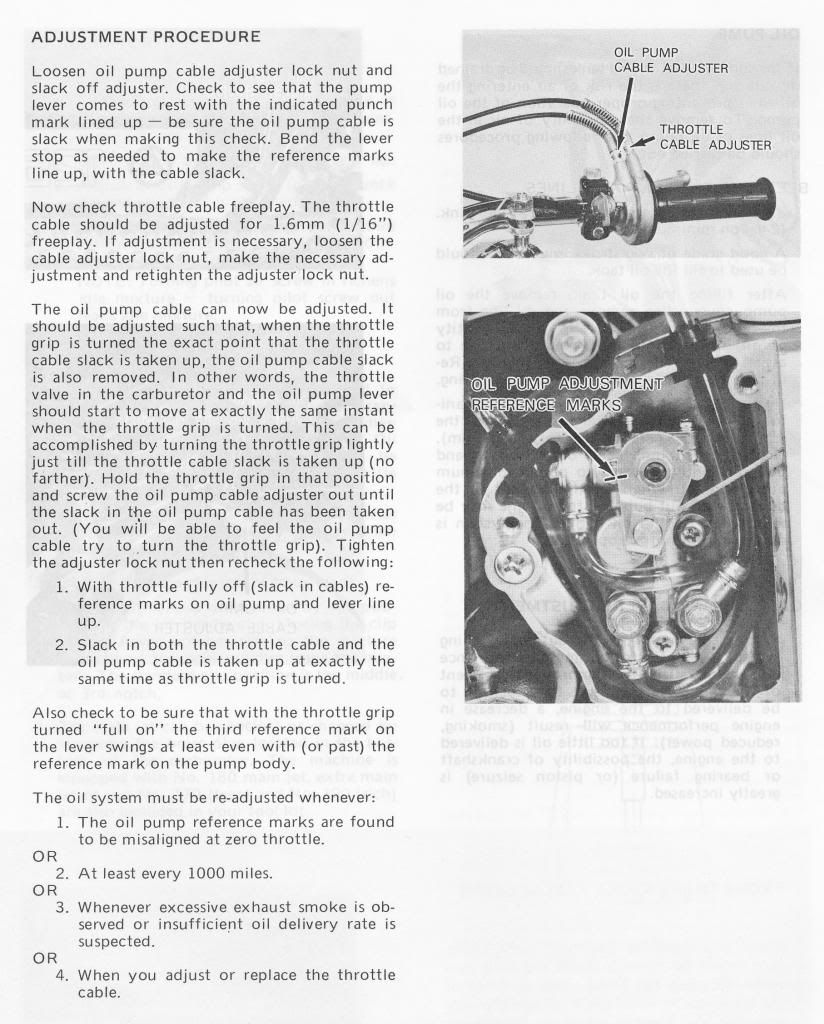

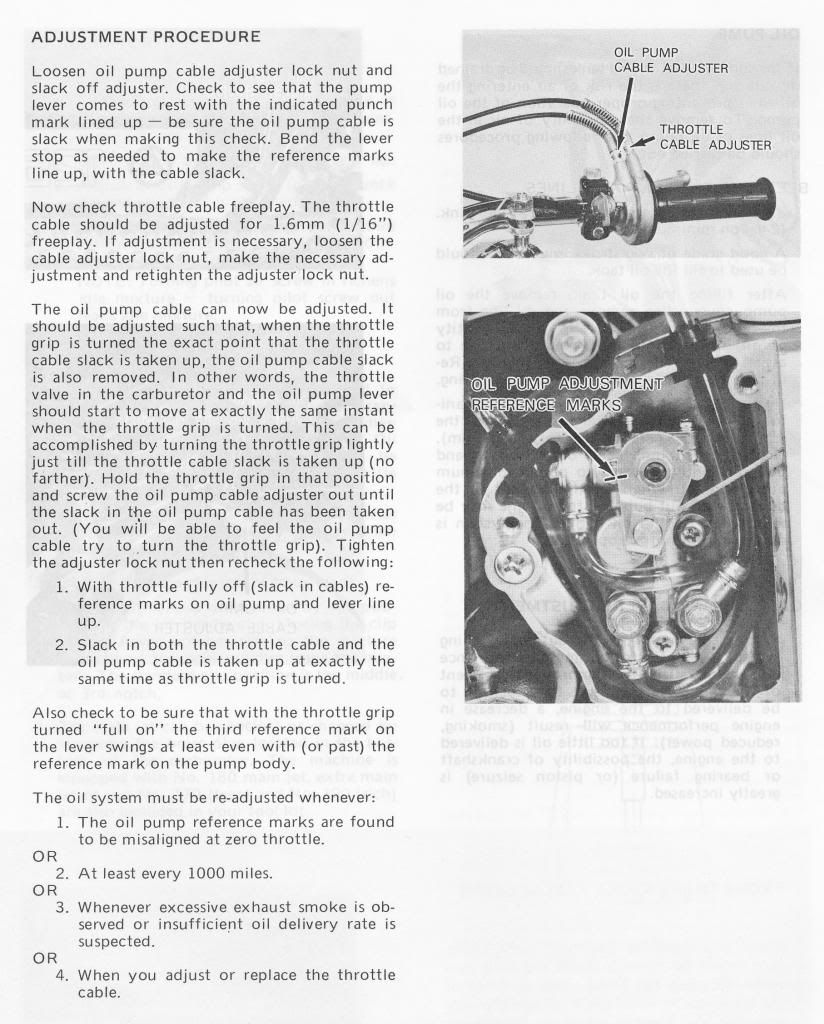

If all goes as planned, there will be a scan of a page from the owner's manual in the middle of this post when I get done.

IF the pump is working correctly, there are two ways for it deliver too much oil.

- if the pump "cam" does not adjusted properly for the "at rest" position - the reference lines must line up when the cable is fully slack or removed

- if the oil pump cable is not adjusted properly, cable tightness may not allow the pump cam to return to the proper "at rest" position at zero throttle. In this case, the pump would always be delivering more oil than is appropriate for the throttle position.

Once adjustment is checked/adjusted things should be better -- 1) cam and pump body reference marks are aligned with slack cable and 2) pump cam starts to move at exactly the same time as the throttle slide starts to move.

Ed

PS: No, you should not even continue thinking about drilling the oiling oil in the Wombat 03 crankcase with the engine in the frame.

PPS: The Wombat 03 engine is the ONLY small bore Hodaka engine which requires this modification when the oil pump is removed.

If all goes as planned, there will be a scan of a page from the owner's manual in the middle of this post when I get done.

IF the pump is working correctly, there are two ways for it deliver too much oil.

- if the pump "cam" does not adjusted properly for the "at rest" position - the reference lines must line up when the cable is fully slack or removed

- if the oil pump cable is not adjusted properly, cable tightness may not allow the pump cam to return to the proper "at rest" position at zero throttle. In this case, the pump would always be delivering more oil than is appropriate for the throttle position.

Once adjustment is checked/adjusted things should be better -- 1) cam and pump body reference marks are aligned with slack cable and 2) pump cam starts to move at exactly the same time as the throttle slide starts to move.

Ed

PS: No, you should not even continue thinking about drilling the oiling oil in the Wombat 03 crankcase with the engine in the frame.

PPS: The Wombat 03 engine is the ONLY small bore Hodaka engine which requires this modification when the oil pump is removed.

Keep the rubber side down!

Re: 03 Wombat oiler issues - different advice from the tech

Danny and Ed thank you !! Perfect information for Dave! Good call on the check valve Danny I had forgotten about that.

Dave like Ed said please please do not drill that hole in the cylinder while the cylinder is on the engine. Take the time to pull it down and you would be best to remove the left main bearing before starting. Like I said on the phone I personally like to run pre-mix and bypass the oil injection but this is a personal preference.

Thanks

Paul

Dave like Ed said please please do not drill that hole in the cylinder while the cylinder is on the engine. Take the time to pull it down and you would be best to remove the left main bearing before starting. Like I said on the phone I personally like to run pre-mix and bypass the oil injection but this is a personal preference.

Thanks

Paul

-

michael_perrett

- Posts: 270

- Joined: Tue Sep 03, 2013 10:41 pm

Re: 03 Wombat oiler issues - different advice from the tech

Danny, do you have the angle in degrees to position the crankcase half prior to drilling the hole? I did it on Rick Mott's 03, but had to rely on guess work to get that angle.

I love the oil injection system on my 175. Works well for me. Going that route for my near completed 250. For those who run on premix, I suggest removing the oil pump and blocking off the hole. One can then return to the oil injection system as an option, knowing that the pump was not run dry.

Mike Perrett

I love the oil injection system on my 175. Works well for me. Going that route for my near completed 250. For those who run on premix, I suggest removing the oil pump and blocking off the hole. One can then return to the oil injection system as an option, knowing that the pump was not run dry.

Mike Perrett

- RichardMott

- Posts: 552

- Joined: Mon Jul 22, 2013 12:36 am

- Location: King of Prussia, Pa

Re: 03 Wombat oiler issues - different advice from the tech

All,

Mike did a good "guess work" angle on my 03.

It has been running great since 2009 using Pennzoil pre-mix.

I too love the 03 motor. Great power band and primary kick.

Rick Mott

Mike did a good "guess work" angle on my 03.

It has been running great since 2009 using Pennzoil pre-mix.

I too love the 03 motor. Great power band and primary kick.

Rick Mott

Rick Mott

In order to be old and wise, you must survive young and stupid!

In order to be old and wise, you must survive young and stupid!

Re: 03 Wombat oiler issues - different advice from the tech

Man... that's some great info. I'm off to pickup a 79 IT400 tank and will be back later today to go through those suggestions. You guys are amazing.

BTW.... yeah I knew the engine needed to come out. Just did all of that so I was not looking forward to doing it again so soon. Hopefully I can get the oiler sorted and be on my way. Again, my sincere thanks to all.

Dave

BTW.... yeah I knew the engine needed to come out. Just did all of that so I was not looking forward to doing it again so soon. Hopefully I can get the oiler sorted and be on my way. Again, my sincere thanks to all.

Dave

Re: 03 Wombat oiler issues - different advice from the tech

Well my old age must be kicking in. I thought I had specs and proceedures on testing oil pump volume but can not find any info. Checked all the Hodaka manuals and nothing listed for models with oil pumps. Must have been thinking about my 74 Kawasaki 750. Personaly I like oil injection and it would be easier to replace the pump than split the engine cases.

Mike,

I did not measure the angle but simply used an early model case to tilt my drill press table to match the angle.

Danny

Mike,

I did not measure the angle but simply used an early model case to tilt my drill press table to match the angle.

Danny

-

michael_perrett

- Posts: 270

- Joined: Tue Sep 03, 2013 10:41 pm

Re: 03 Wombat oiler issues - different advice from the tech

Danny, I would be interested in the pump testing info, as well as the any information on identifying pump models if you find it. Also, what model of Kawasaki 750 do you have? A three cylinder, two stroke?

Mike

Mike

- Bullfrog

- Posts: 2796

- Joined: Mon Jul 22, 2013 4:05 pm

- Location: Oregon, 12 miles from the center of the Hodaka Universe(Athena)

Re: 03 Wombat oiler issues - different advice from the tech

While I remember working with the oil pumps a bit wayeeee back when . . . I don't think I ever saw any "factory specs" (Mikuni factory) or Hodaka factory specs on pump output. In the Service Dept., the quandary was "What test could be designed which was repeatable and definitive without special test equipment?" For us, the answer came down to, "It is a positive displacement pump. So, if it actually pumps oil . . . then it is working as designed." Make sure the reference lines match up with slack cable and make sure the cam starts to move at exactly the same instant as the throttle slide . . . and oil will be delivered at the design rate (whatever that is).

Ed

Ed

Keep the rubber side down!

-

michael_perrett

- Posts: 270

- Joined: Tue Sep 03, 2013 10:41 pm

Re: 03 Wombat oiler issues - different advice from the tech

A test bench could be built, electic motor driven, certain RPM and info on flow volume at least and pressure at the volume measurement. Would be nice to be used with pumps with an unknown history. A pump run dry, one would imagine would have some internal damage, let alone the possibility of using a Road Toad pump on a 250, for example.

Mike

Mike

Re: 03 Wombat oiler issues - different advice from the tech

Here is the hole (if I uploaded right)

- Bullfrog

- Posts: 2796

- Joined: Mon Jul 22, 2013 4:05 pm

- Location: Oregon, 12 miles from the center of the Hodaka Universe(Athena)

Re: 03 Wombat oiler issues - different advice from the tech

Mike:

There you go. Electric drive, oil supply tank, precisely graduated oil catch tank . . . possibly a means for testing output pressure . . . or even a method for testing output at a pre-set pressure. Not at all an easy project. And back in the day, it was pretty safe to go with, "If it pumps oil, its good." I remember you could even see the pressure pulses (which were quite slow) when holding the output end of an oil line and closely watching the oil flow.

Such a testing machine probably has more utility today than it did wayeeee back when. Though I suspect that even if a person "cornered" the market on Mikuni oil pump testing for the whole country . . . it might take a few years to achieve "break even" on the cost of building the testing equipment. I don't think I'm going to build an oil pump test station. You?

Ed

There you go. Electric drive, oil supply tank, precisely graduated oil catch tank . . . possibly a means for testing output pressure . . . or even a method for testing output at a pre-set pressure. Not at all an easy project. And back in the day, it was pretty safe to go with, "If it pumps oil, its good." I remember you could even see the pressure pulses (which were quite slow) when holding the output end of an oil line and closely watching the oil flow.

Such a testing machine probably has more utility today than it did wayeeee back when. Though I suspect that even if a person "cornered" the market on Mikuni oil pump testing for the whole country . . . it might take a few years to achieve "break even" on the cost of building the testing equipment. I don't think I'm going to build an oil pump test station. You?

Ed

Keep the rubber side down!

Re: 03 Wombat oiler issues - different advice from the tech

Quick update.... Man I have been going through plugs like crazy because of all of the mix/oil that was originally getting into the engine. So I tested the banjo fittings and I could not blow or suck air from the tube I had attached so I'm guessing they are ok. So I drained the tank of all traces of mix. Filled with straight gas, Ran engine out of gas, primed all the oiler lines and fired it up. Ran ok.... then I tried to burp the top phillips screw bleeder and that was not good..... engine started to bog and from that point on it wouldn't idle and seemed like it was loaded up. Wondering if a hotter plug would help as I'm using the NGK B8HS right now. Going to put another new one in and I bet it runs like a top.... for a while. Didn't have the massive smoke though which was good. When I took her out on the road it's like it occasionally finds that sweet spot of power for a second then it's just blaaaa then it kicks in again with this same repetitive symptom.

- Bullfrog

- Posts: 2796

- Joined: Mon Jul 22, 2013 4:05 pm

- Location: Oregon, 12 miles from the center of the Hodaka Universe(Athena)

Re: 03 Wombat oiler issues - different advice from the tech

No - do not use a hotter plug. That is NOT the problem. (and going to a hotter plug could endanger your engine)

You tried to "burb the top bleeder screw" . . . I don't know what that means. Please elaborate.

NOTE: If it acts loaded up . . . maybe it IS loaded up. Do we know for sure that your float valve is operating as it should?

Ed

You tried to "burb the top bleeder screw" . . . I don't know what that means. Please elaborate.

NOTE: If it acts loaded up . . . maybe it IS loaded up. Do we know for sure that your float valve is operating as it should?

Ed

Keep the rubber side down!

Re: 03 Wombat oiler issues - different advice from the tech

I'm beginning to think Ed may be onto the problem. Maybe it is not over oiling. Maybe it is the carb float. Maybe even a spec of dirt keeping the float valve from shutting off and the smoke is from gas flooding into the cylinder. Check that out before you go any further with oil.

Bill Chapman, Monument, CO

Raced and Modified Hodakas in Statesville NC back in the day.

Raced and Modified Hodakas in Statesville NC back in the day.

Re: 03 Wombat oiler issues - different advice from the tech

The oiler has two phillips head screws that allow you to burp the oil lines (To remove any air). The lower works on the line from the oil reservoir to the oiler and the other is from the oiler to your case and carb intake. You know I was thinking about that (The carb issue) because I have seen drips coming out the overflow tubes on the carb lately. I think it's time to take the carb out and sniff around some. Thanks again for your thoughts.

Dave

Dave

Re: 03 Wombat oiler issues - different advice from the tech

Downerman,

I am a little confused by this statement, "then I tried to burp the top phillips screw bleeder and that was not good..... engine started to bog and from that point on it wouldn't idle and seemed like it was loaded up". If you are loosening one of the screws on the oil pump to bleed the system that would be incorrect and might cause problems. Loosening the wrong screw on the pump and then re-tightening it might cause interal pump parts to be out of position and possible damage.

Bleeding the oil pump system is performed by..

1. Remove oil tank feed line from oil pump and allow to drain into container until all air is removed. Then re-connect to oil pump.

2. Mix up some 32:1 two stroke oil and gas and pour in fuel tank.

3. Remove the oil line from the intake manifold fitting.

4. Start engine and adjust to fast idle..approxomately 3000 rpm

5. Grasp oil pump cable outer housing and pull out until it stops...oil pump lever should be at max out put position

6. When oil trickles from line with out air bubbles re-connect oil line.

This is a summary from the 03 Wombat manual. No mention is made to bleed the crankcase line.

Frankly I do not think SHORT term low speed operation of the engine on pre-mix would do any harm to the left crank seal or bearing. With that said a short test run with the oil pump lines plugged and the oil pump cable dis-connected at the pump would allow you to verify or eliminate the oil system as your problem. I know I am stepping out on a limb here but I think there would be sufficient lube to the bearing and seal under these conditions. Probably should dis-connect the oil pump cable and remove from the throttle end also in order to prevent the the cable from binding and sticking the throttle open. Waiting for the flames.

Danny Cooke

I am a little confused by this statement, "then I tried to burp the top phillips screw bleeder and that was not good..... engine started to bog and from that point on it wouldn't idle and seemed like it was loaded up". If you are loosening one of the screws on the oil pump to bleed the system that would be incorrect and might cause problems. Loosening the wrong screw on the pump and then re-tightening it might cause interal pump parts to be out of position and possible damage.

Bleeding the oil pump system is performed by..

1. Remove oil tank feed line from oil pump and allow to drain into container until all air is removed. Then re-connect to oil pump.

2. Mix up some 32:1 two stroke oil and gas and pour in fuel tank.

3. Remove the oil line from the intake manifold fitting.

4. Start engine and adjust to fast idle..approxomately 3000 rpm

5. Grasp oil pump cable outer housing and pull out until it stops...oil pump lever should be at max out put position

6. When oil trickles from line with out air bubbles re-connect oil line.

This is a summary from the 03 Wombat manual. No mention is made to bleed the crankcase line.

Frankly I do not think SHORT term low speed operation of the engine on pre-mix would do any harm to the left crank seal or bearing. With that said a short test run with the oil pump lines plugged and the oil pump cable dis-connected at the pump would allow you to verify or eliminate the oil system as your problem. I know I am stepping out on a limb here but I think there would be sufficient lube to the bearing and seal under these conditions. Probably should dis-connect the oil pump cable and remove from the throttle end also in order to prevent the the cable from binding and sticking the throttle open. Waiting for the flames.

Danny Cooke

- Bullfrog

- Posts: 2796

- Joined: Mon Jul 22, 2013 4:05 pm

- Location: Oregon, 12 miles from the center of the Hodaka Universe(Athena)

Re: 03 Wombat oiler issues - different advice from the tech

Danny:

You won't get a "flame" from me.

If I understand things correctly -- the upper oil line banjo bolt was loosened to "burp" the system. While it is an interesting idea . . . that process can't possibly remove ALL the air. So in that sense it is not a good idea . . . but I don't think there is any possible way of causing pump damage by doing so. Of course it could have been some other screw which was loosened and re-tightened -- in which case you've probably got a good point.

In any case - bleeding the system per the instructions is the best way to go about it.

I am still convinced that IF the pump cam is properly positioned at rest AND the pump cable is properly adjusted . . . then the pump itself is not causing "over-oiling". To quote Sherlock, "There is something afoot!" We need to help find out what that "something" is.

I'd like to know the specs on all the internal carb components and the setting of the pilot air screw for starters. Also the condition of the starter circuit plunger and bore.

Ed

You won't get a "flame" from me.

If I understand things correctly -- the upper oil line banjo bolt was loosened to "burp" the system. While it is an interesting idea . . . that process can't possibly remove ALL the air. So in that sense it is not a good idea . . . but I don't think there is any possible way of causing pump damage by doing so. Of course it could have been some other screw which was loosened and re-tightened -- in which case you've probably got a good point.

In any case - bleeding the system per the instructions is the best way to go about it.

I am still convinced that IF the pump cam is properly positioned at rest AND the pump cable is properly adjusted . . . then the pump itself is not causing "over-oiling". To quote Sherlock, "There is something afoot!" We need to help find out what that "something" is.

I'd like to know the specs on all the internal carb components and the setting of the pilot air screw for starters. Also the condition of the starter circuit plunger and bore.

Ed

Keep the rubber side down!

Who is online

Users browsing this forum: No registered users and 2 guests