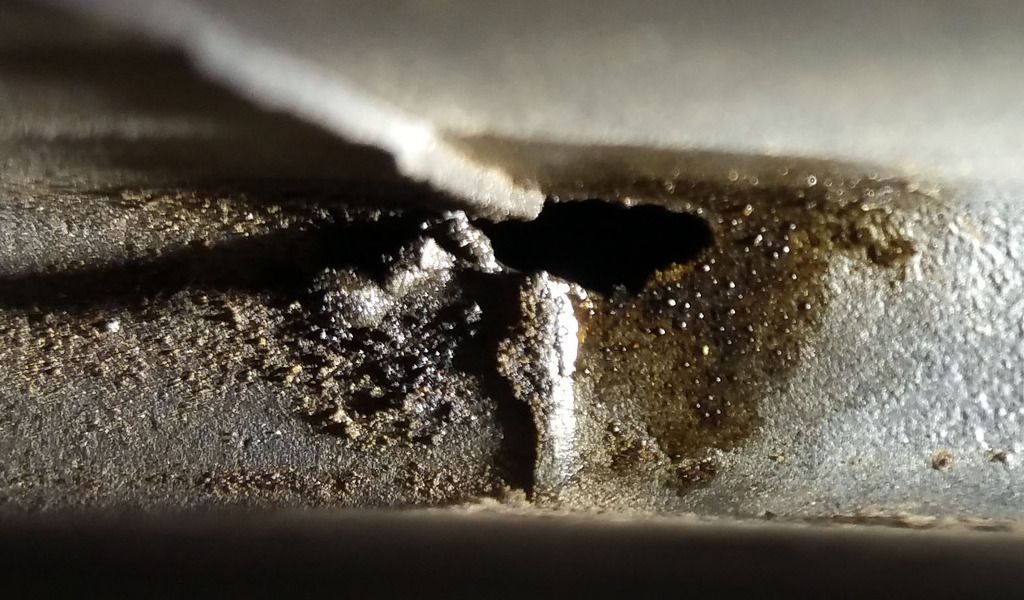

The photo is looking between the 2nd and 3rd fins (from the top) of the cylinder on the left side. This is at a point above the transfer port. As you can see, the casting flaw is "wet" - indicating that it IS a "leak". The engine has been run for years without damage, indicating that the "leak" passage is long and convoluted and small. There is a matching casting flaw on the other side of the cylinder (same place, other side) - but it is "dry" - so almost certainly not a "leak". As if that wasn't enough, there is yet another casting flaw on the centerline of the cylinder at the rear (intake side, also between the 2nd and 3rd fins). Thankfully, this one appears to be "dry" too.

So here is the question, do any of you folks who have running 250 engines see the same sort of casting flaw on your cylinder? I would expect not, but I am curious. The engine in question has always been a "poor runner" for its current owner . . . perhaps now we know why. Unfortunately I'm pretty sure it is too late to file a Warranty Claim.

Ed