Day One - New Project

Re: Day One - New Project

Here's what I think is happening and I'm about 98% sure. The clips go in but with a contact fit against the pin. As the pin heats up it gets longer. Before it pushes the clip out of the groove it begins to distort the piston. The already minimum fit piston is pushed apart and the piston deforms at its weakest point which is at 90 degrees from the pin on the intake side where the intake/transfer holes are. This is exactly where the piston seized. When the engine starts it seems normal but as it reaches operating temperature it begins to drag with inconsistent idling problems. As you come off of idle more jets open and more fuel and lubricant free the drag and it runs fine with a burst of power. Seizure is occurring as it approaches idle again which is all consistent with what I'm experiencing. When you disassemble the engine the clearances are normal again. The cure will be to shorten the pin (if it hasn't done too much damage). We'll see.

And Doug, thanks for your measurements. The Hodaka clip appeared to be very slightly larger in wire diameter but did appear to seat in the groove even though tight against the pin.

Max

And Doug, thanks for your measurements. The Hodaka clip appeared to be very slightly larger in wire diameter but did appear to seat in the groove even though tight against the pin.

Max

Re: Day One - New Project

After mathematically computing roughly what gain in length would a 2" pin heated and additional 300 degrees I came up with a gain in length of .0028". Being rusty at math after all these years, I checked myself by measuring a pin and then heating it until oil began to smoke and noting a gain in length of .002". Distorting the piston this much with only .002" clearance to begin with seems to confirm my theory.

Max.

Max.

Re: Day One - New Project

That is not what is happening...hodakamax wrote:Here's what I think is happening and I'm about 98% sure. The clips go in but with a contact fit against the pin. As the pin heats up it gets longer. Before it pushes the clip out of the groove it begins to distort the piston. The already minimum fit piston is pushed apart and the piston deforms at its weakest point which is at 90 degrees from the pin on the intake side where the intake/transfer holes are. This is exactly where the piston seized. When the engine starts it seems normal but as it reaches operating temperature it begins to drag with inconsistent idling problems. As you come off of idle more jets open and more fuel and lubricant free the drag and it runs fine with a burst of power. Seizure is occurring as it approaches idle again which is all consistent with what I'm experiencing. When you disassemble the engine the clearances are normal again. The cure will be to shorten the pin (if it hasn't done too much damage). We'll see.

And Doug, thanks for your measurements. The Hodaka clip appeared to be very slightly larger in wire diameter but did appear to seat in the groove even though tight against the pin.

Max

- Bullfrog

- Posts: 2795

- Joined: Mon Jul 22, 2013 4:05 pm

- Location: Oregon, 12 miles from the center of the Hodaka Universe(Athena)

Re: Day One - New Project

I had completely overlooked a situation on this build which likely is a major contributor to the current problem, but first a question on the piston pin/circlip situation.

Am I understanding things correctly? The Hodaka circlips have NOT been used in the running engine, and ONLY the Wiseco circlips have been used? It is essential that the Wiseco circlips be used in the Wiseco piston to assure full seating of the circlips in their grooves - then it will be physically impossible for the pin to push the circlip out of the groove.

I am not persuaded that piston pin heat growth is pushing against the circlips at both ends and causing distortion of the piston and thus causing seizures. I don't want to type long enough to explain why I am not persuaded . . . but I'm not.

The head pipe on this machine appears to be considerably longer than the one on my 125cc Trials engine. While I can offer no direct experience regarding why it might be too long and therefore causing problems . . .

. . . it is on the outside of my experience envelope and therefore is of some concern. I have been able to jet reasonably well on the trials machine, but the engine is pretty much "done" by about 5,000 rpm with the very long head pipe - so the head pipe alone is not likely the cause of problems in

continued . . .

Am I understanding things correctly? The Hodaka circlips have NOT been used in the running engine, and ONLY the Wiseco circlips have been used? It is essential that the Wiseco circlips be used in the Wiseco piston to assure full seating of the circlips in their grooves - then it will be physically impossible for the pin to push the circlip out of the groove.

I am not persuaded that piston pin heat growth is pushing against the circlips at both ends and causing distortion of the piston and thus causing seizures. I don't want to type long enough to explain why I am not persuaded . . . but I'm not.

The head pipe on this machine appears to be considerably longer than the one on my 125cc Trials engine. While I can offer no direct experience regarding why it might be too long and therefore causing problems . . .

. . . it is on the outside of my experience envelope and therefore is of some concern. I have been able to jet reasonably well on the trials machine, but the engine is pretty much "done" by about 5,000 rpm with the very long head pipe - so the head pipe alone is not likely the cause of problems in

continued . . .

Keep the rubber side down!

- Bullfrog

- Posts: 2795

- Joined: Mon Jul 22, 2013 4:05 pm

- Location: Oregon, 12 miles from the center of the Hodaka Universe(Athena)

Re: Day One - New Project

. . . continued . . .

this situation. But it may well be important when combined with the intake manifold situation. (Note that my trials engine has the carb mounted directly to the normal reed manifold.)

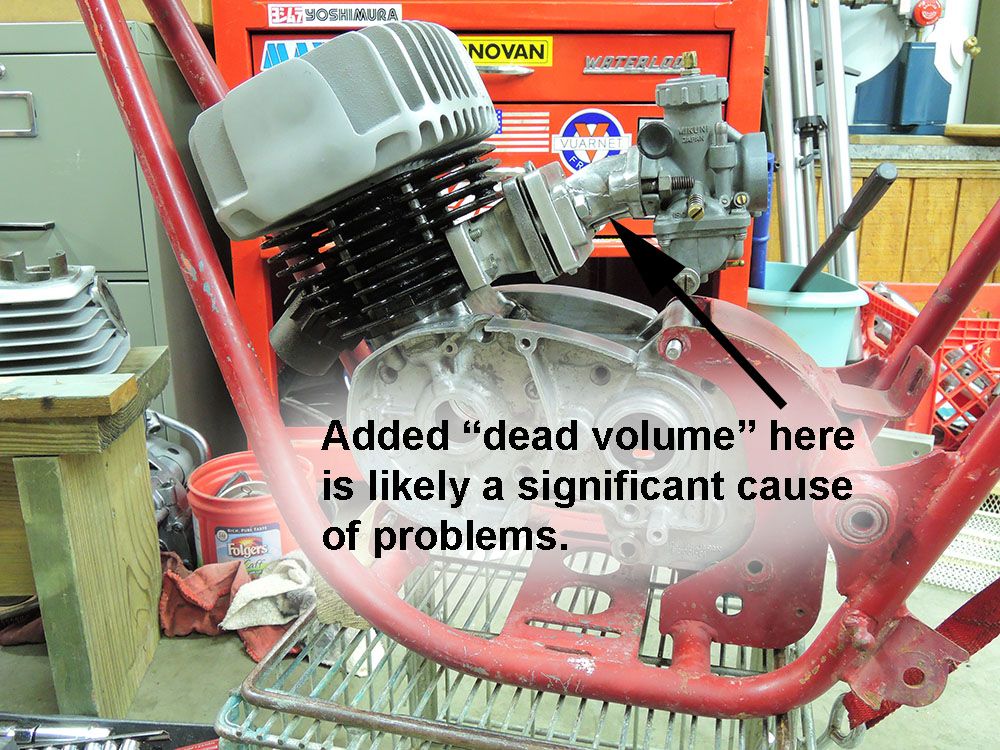

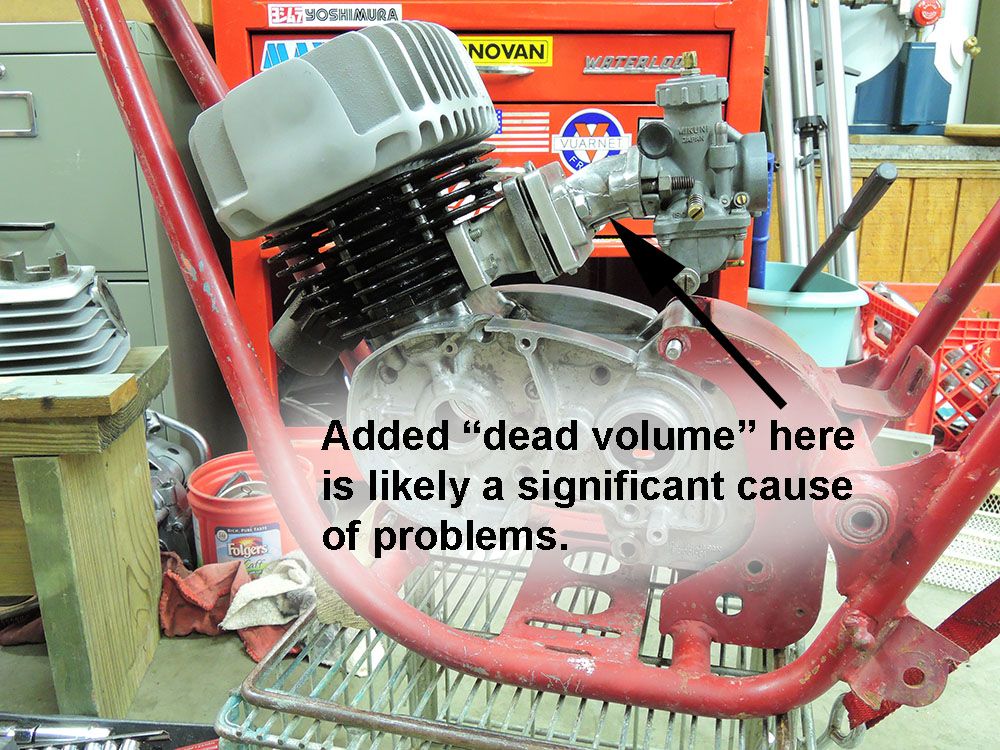

I had not noticed the "stacking" of a normal piston port manifold between the carb and the reed manifold until this morning during a review of the "build". This is quite likely THE primary culprit causing the inability to tune the carb and causing the seizures.

The added length and volume of the intake tract is wreaking all kinds of havoc with the intake processes. I would recommend that the extra manifold be removed immediately and bolt the carb up directly to the reed manifold . . . then things will probably start to work and react the way they ought to.

Sorry I didn't notice the intake situation long ago.

Ed

this situation. But it may well be important when combined with the intake manifold situation. (Note that my trials engine has the carb mounted directly to the normal reed manifold.)

I had not noticed the "stacking" of a normal piston port manifold between the carb and the reed manifold until this morning during a review of the "build". This is quite likely THE primary culprit causing the inability to tune the carb and causing the seizures.

The added length and volume of the intake tract is wreaking all kinds of havoc with the intake processes. I would recommend that the extra manifold be removed immediately and bolt the carb up directly to the reed manifold . . . then things will probably start to work and react the way they ought to.

Sorry I didn't notice the intake situation long ago.

Ed

Keep the rubber side down!

Re: Day One - New Project

Enjoying this discussion immensely. I agree with Ed-- the intake manifold length is critical in any engine. And especially so with a 125cc displacement engine. I have no idea what complications are added with the 2-stroke induction cycle.

I've toyed with the idea of getting time on a dyno and checking the mixture under load conditions.

All this talk about piston pin clips has gotten me paranoid. Mine just snicked right in and I didn't double/triple check the wire clip (I always put one clip in on the bench, and the other with the piston/pin installed). I think I put the wire clip tang on the bottom.

Carry on...

I've toyed with the idea of getting time on a dyno and checking the mixture under load conditions.

All this talk about piston pin clips has gotten me paranoid. Mine just snicked right in and I didn't double/triple check the wire clip (I always put one clip in on the bench, and the other with the piston/pin installed). I think I put the wire clip tang on the bottom.

Carry on...

Keepin' the Shiny Side up

on a '72 Wombat 94

--Bill

on a '72 Wombat 94

--Bill

Re: Day One - New Project

Ed, that was a concern early on and I did remove the manifold and continued to test all of the slides at that point. What started me to thinking about the pin clearance theory is two things. First it appeared that I had two different problems, both unusual and unlikely. With testing it was confirmed that the pin is getting .002"+ longer after warm up starting with zero clearance. Everything is falling into place with cause and effect. The pin cannot grow that amount without distorting an already snug piston and eventually ejecting the clip. All of the clues seem to be related to the pin clearance.

Also, you are right about the long header pipe causing the engine to be done at around 5000 RPMs but the mid-range seems quite strong. I need to appraise the damage at this point, find the proper clips and shorten or replace the pin. I've run out of time this week with two other bikes to prep for the upcoming Car/Motorcycle this Saturday.

As always I appreciate and thank you and everyone else for their advice. The Forum is good thing! This would be a good one for a beer bet--any takers? I'm still with my 98% chance of being right and may even offer odds.

I'm still with my 98% chance of being right and may even offer odds.

Later,

Maxie

Also, you are right about the long header pipe causing the engine to be done at around 5000 RPMs but the mid-range seems quite strong. I need to appraise the damage at this point, find the proper clips and shorten or replace the pin. I've run out of time this week with two other bikes to prep for the upcoming Car/Motorcycle this Saturday.

As always I appreciate and thank you and everyone else for their advice. The Forum is good thing! This would be a good one for a beer bet--any takers?

Later,

Maxie

-

Bruce Young

- Posts: 493

- Joined: Wed Jul 24, 2013 6:48 am

Re: Day One - New Project

Max I have to agree with Ed, Thru lots of years racing conversations and etc. I have heard lots of talk about length of header pipe, tail pipe and center pipe size, and its relationship to performance in a 2 stroke engine, also the intake length relationship. It was best explained by road racing people in the old days whom needed all these measurements to be exact to get max out of a 2 stroke engine. I know that there is an exact science to this and one can take measurement and calculate exactly what type of performance is expected, but all things have to be in harmony to get the very best. Seat of the pants does not work. 'There are charts out there in the racing world that will give you the formula, I might suggest trying to talk to an expert road racer tuner whom has to make these formula,s work all the time. Four stroke formulas are different. Maybe contact Leo Vince exhaust systems in Northern Calif. talk to Tim Calhoun, he is an expert. This whole project is something that all Hodaka persons whom wish to get max performance think about and follow. Your project is a great work in progress and it has brought out great idea,s from lots of persons. Made them think a little bit. Bruce Young PS as an example I witnessed Kenny Roberts take a ball bean hammer to a pipe on his 2 stoke triple mile bike one day to make final adjustment to the way the bike ran and performed, by denting the pipe ever so slightly, in the end he got what he wanted and it ran like a striped ape. I saw this also done at road races and on the Pro MX circuit in the old two stroke days. . Just a side story.

Bruce Young - HodakaPartsIdaho

Re: Day One - New Project

I should also add that as the project began I researched ways to improve low-end performance and this is one of the articles that I based my new engine on. Notice that Harry Taylor also recommended the reeded 24mm carb with leveling with the stock manifold and a lengthening of the header pipe to be 18-21'' long, mine being 20''. My engine is just like that. I didn't just make all this up.  Check it out especially the second paragraph under carburetion.

Check it out especially the second paragraph under carburetion.

Max

PS--At least we're getting a good discussion out of all this and I have presented evidence with tests, measurements and research on my theory. The problem is I'm not getting any rebuttal on where the extra .002''+ length of the pin is going. Perhaps it's going into the space between the piston and cylinder that is only that width to begin with. Is anyone reading this? I seriously doubt that Harry Taylor was wrong on this one.

Max

PS--At least we're getting a good discussion out of all this and I have presented evidence with tests, measurements and research on my theory. The problem is I'm not getting any rebuttal on where the extra .002''+ length of the pin is going. Perhaps it's going into the space between the piston and cylinder that is only that width to begin with. Is anyone reading this? I seriously doubt that Harry Taylor was wrong on this one.

Last edited by hodakamax on Tue Sep 20, 2016 9:21 am, edited 2 times in total.

Re: Day One - New Project

Max... Kels thinks Ed has it right... Look in to what he suggests and you will solve your issues.

Kels is surprised that the engine will even run a low speeds... Also if you are running a very thick reed petal, that will amplify the issues you are having....

The idea that the pin is expanding and distorting the piston is not likely or probable.. Ya, Kels will take the bet.....

Keep in mind the piston is also expanding? NOT just the pin..

Kels is surprised that the engine will even run a low speeds... Also if you are running a very thick reed petal, that will amplify the issues you are having....

The idea that the pin is expanding and distorting the piston is not likely or probable.. Ya, Kels will take the bet.....

Keep in mind the piston is also expanding? NOT just the pin..

- Bullfrog

- Posts: 2795

- Joined: Mon Jul 22, 2013 4:05 pm

- Location: Oregon, 12 miles from the center of the Hodaka Universe(Athena)

Re: Day One - New Project

I was guesstimating the header pipe at 24" or more, so I was mistaken about that. At 20", that is inside my experience envelope . . . and can be jetted to run properly.

But on the intake side, HT modified the reed manifold to fit to the cylinder and fitted the carb to the reed manifold - the centerline of the carb slide is well forward of the upper rear engine mount bolt. The 1/4" micarta heat block mentioned in the tuning sheet increased the intake tract length only about 1/8th of the increase on your scooter (approximation based on a guestimated length of 2" for the piston port manifold added to the system). HT was not intentionally lengthening the intake tract. He was accepting a minor amount of lengthening in order to level the carb for improved running on steep downhill situations.

Oh yeah, put me down for the beer bet too. (A nice Porter would be good. )

)

Ed

But on the intake side, HT modified the reed manifold to fit to the cylinder and fitted the carb to the reed manifold - the centerline of the carb slide is well forward of the upper rear engine mount bolt. The 1/4" micarta heat block mentioned in the tuning sheet increased the intake tract length only about 1/8th of the increase on your scooter (approximation based on a guestimated length of 2" for the piston port manifold added to the system). HT was not intentionally lengthening the intake tract. He was accepting a minor amount of lengthening in order to level the carb for improved running on steep downhill situations.

Oh yeah, put me down for the beer bet too. (A nice Porter would be good.

Ed

Keep the rubber side down!

Re: Day One - New Project

Nope, here it is out of the same article. Mine is actually shorter than Harry's in-that I didn't use the heat block. I had to pull the studs out of the manifold and turn them around to be able to get the carb on without the studs interfering with the carb body.

Max

Edit. Harry used a 93 manifold and I used a 94 which is longer but by removing the heat block they are about the same length.

Max

Edit. Harry used a 93 manifold and I used a 94 which is longer but by removing the heat block they are about the same length.

Last edited by hodakamax on Tue Sep 20, 2016 10:49 am, edited 1 time in total.

Re: Day One - New Project

Kels thinks Max should look closer at the relationship of the carb with respect to the engine mount in HT's pic vs Max's.. Max's is clearly back at least 1-2" further.. Max's adapters are longer..

Re: Day One - New Project

Hmmm, I'm getting a lot of advice from several people telling me that a steel pin expanding by .002''+ can't change the shape of an aluminum piston. This happens before the clip is finally pushed out and the pin tries to go into the transfer port. When you jack the piston apart at the pin bosses, the piston gets bigger in the bore. There's clearance in the pin area because it has more clearance there, but putting a bigger piston in the bore soon eats up it's .002'' clearance required to run without seizing. We are only talking about expanding the piston size not more than .0005'' to initiate a seizure. I find that quite possible and highly likely. Big clues here. The pin eventually pushes the clip out which would really be hard to do as the pin should be forcing it into the groove deeper. Also the piston is seizing when it's not even under performance stress and all of this is happening at the same time? I also think that the piston has been damaged beyond repair because of the enlarging of the clip groove. This will be something to look for in post inspection. Still my opinion but sounds much more likely than the other purposed ideas that I'm hearing.

Max

Max

Re: Day One - New Project

You know that all of the evidence I'm getting against my case would be considered "hear-say'' in court of law or scientific publication. Kel's has my carb 1-2" further from the engine than it actually is. Others are saying that the piston can't be pushed apart because they think so. I've provided evidence that Harry Taylor recommended the same set-up while people are looking at what they want to. I have made a simple case that seems reasonable at least to me. The pin does get .002'+ longer with heat and doesn't have any place to go but to expand the piston. Nobody is providing any other evidence except "I think so.'' If you don't believe what I'm saying or someone is not reading what I say, which is probably what's happening, at least tear my theory apart with facts. I hope I'm not sounding "mean" but I'm somewhat worn down with this project and trying to actually close the case with facts rather than adding new "un-proveables". I call this Hoo-doo chasing where others lead you down the wrong path without some sort of evidence. Sorry gang but I've had this thing apart about 15 times and have a forty hour work week in this problem. Not in the great mood but improving. Love you all except Kels.  or

or

Maxie

PS--I hope I don't have to eat a crow!

Maxie

PS--I hope I don't have to eat a crow!

Re: Day One - New Project

Well, I have to admit, it did make me laugh--Just what I needed.

Re: Day One - New Project

Max...

The cylinder is also growing (fact)

The piston is also growing (including the distance between the pin and clip)

The piston always distorts under load (and those added holes amplify the distortion)

Even if the pin is growing under heat (which I am sure it is BUT.. see above) it will not cause any added forces on the piston skirts.

Max's theory is only valid IF the pin is the only object growing (Not happening)

Here is what Kels thinks is happening..

1) Your exhaust header (cool as it is) is NOT functionable (too long and curvy) The header section to 1st difuser controls the suction pulse to the cylinder which does MOST of the scavenging to pull F/A up the transfer ducts into the cylinder.. Kels would guess that you have NONE of this effect happening and are solely relying on "OLD SCHOOL" crankcase pumping action.. Not the main player with a TUNED exhaust system.. basically , youhave removed the "TUNE" from your "Tuned" Exhaust system.. Shorten it up to stock length and all will be much better...

2) Your carb intake track is simply too long.. THIS COUPLED with the lack of a properly functioning exhaust system is impeding flow from the carb to the cylinder..

Kels is not basing this on theory but real work experiences.. Kels is TRYING to help!! MAX will not like the taste of Crow.. Max should listen to Kels and others and just perform the changes and then experience the result...

The cylinder is also growing (fact)

The piston is also growing (including the distance between the pin and clip)

The piston always distorts under load (and those added holes amplify the distortion)

Even if the pin is growing under heat (which I am sure it is BUT.. see above) it will not cause any added forces on the piston skirts.

Max's theory is only valid IF the pin is the only object growing (Not happening)

Here is what Kels thinks is happening..

1) Your exhaust header (cool as it is) is NOT functionable (too long and curvy) The header section to 1st difuser controls the suction pulse to the cylinder which does MOST of the scavenging to pull F/A up the transfer ducts into the cylinder.. Kels would guess that you have NONE of this effect happening and are solely relying on "OLD SCHOOL" crankcase pumping action.. Not the main player with a TUNED exhaust system.. basically , youhave removed the "TUNE" from your "Tuned" Exhaust system.. Shorten it up to stock length and all will be much better...

2) Your carb intake track is simply too long.. THIS COUPLED with the lack of a properly functioning exhaust system is impeding flow from the carb to the cylinder..

Kels is not basing this on theory but real work experiences.. Kels is TRYING to help!! MAX will not like the taste of Crow.. Max should listen to Kels and others and just perform the changes and then experience the result...

Re: Day One - New Project

Kels, you know my soft spot is humor, it should be in life and you finally lure me into a response (just one more time). Of course the bore gets bigger too with heat but the piston has the added burden of being denied the minute clearance it needs to prevent seizure due to the deformation of the piston caused by the pin against the clips. You still need the .002'' clearance to prevent seizure. Pretty obvious and clear. Think about it. Let's consider the plausible vs Hoodoo chasing. My system is based on a successfully operating system by a person most knowledgeable in Hodaka history that we know of. We all can be fallible but in this case things seem to be adding up. New odds 3 beers to my one, I do pay off.

Max

BTW Aluminum expands almost twice as much as iron under heat which means more heat= less clearance. A dragging piston is closing tolerances at twice the rate of iron. It's all downhill from there. Eminent seizure coming up.

Max

BTW Aluminum expands almost twice as much as iron under heat which means more heat= less clearance. A dragging piston is closing tolerances at twice the rate of iron. It's all downhill from there. Eminent seizure coming up.

Last edited by hodakamax on Tue Sep 20, 2016 2:31 pm, edited 1 time in total.

Re: Day One - New Project

And remember, the coefficient (rate) of expansion of Aluminum is about 3x that od steel, so if you have any pin-to-clip clearace when cold, you'll have even more when it's at op.temp. My opinion is that the clips must fit tbe groooves in the piston-- use Wiseco with Wiseco.

My 2c.

My 2c.

Keepin' the Shiny Side up

on a '72 Wombat 94

--Bill

on a '72 Wombat 94

--Bill

Re: Day One - New Project

All true Bill, new Wiseco clips to be ordered. Still to be determined which clip left last time. Whichever one left first still didn't prevent the last seizure! Obviously the pin is too long methinks.

Max

PS--Even though this experience has been notably bad, at least the discussion has been really fun. Pluses and minuses we say.

Max

PS--Even though this experience has been notably bad, at least the discussion has been really fun. Pluses and minuses we say.

- Bullfrog

- Posts: 2795

- Joined: Mon Jul 22, 2013 4:05 pm

- Location: Oregon, 12 miles from the center of the Hodaka Universe(Athena)

Re: Day One - New Project

Maxie, the comparison of HT's trials engine induction with the 24mm carb appears to be only slightly shorter over-all than yours . . . but the "sections" of the intake system have some potentially significant differences. The reed manifold on HT's engine appears to be longer than the one on your engine, but more importantly (I think) the extra length between the reed manifold and carb on the HT bike is about 1/2 the length of the extra manifold on the Maxie scooter. That extra induction length/volume between the reeds and the carb may well be past some "tipping point". I have no direct experience/evidence to document that, so value the comment as you will.

I readily admit that I don't KNOW what is causing the seizures, but considering that cylinder, piston, and pin all grow with the heat of operation - I remain unconvinced by the "pin is too long theory".

I remain considerably concerned by the vertical scratches which are quite evident and wide spread in both piston and cylinder . . . so I'll throw another wad of stuff up against the wall to see if anything sticks. 1) Did the cylinder get fully washed after boring to remove machining crumbs? Is the rod big end bearing shedding material(possibly due to #1)? Ditto mag side main bearing? It just seems like there is more vertical scratching than the circlip/piston pin coming loose would have generated. 4) Is the piston pin an easy thumb push fit in the piston? (A too tight fit of the pin in the piston is enough to cause seizures with the OEM Art pistons. It is probably the same with the Wiseco.)

G'night all,

Ed

I readily admit that I don't KNOW what is causing the seizures, but considering that cylinder, piston, and pin all grow with the heat of operation - I remain unconvinced by the "pin is too long theory".

I remain considerably concerned by the vertical scratches which are quite evident and wide spread in both piston and cylinder . . . so I'll throw another wad of stuff up against the wall to see if anything sticks. 1) Did the cylinder get fully washed after boring to remove machining crumbs? Is the rod big end bearing shedding material(possibly due to #1)? Ditto mag side main bearing? It just seems like there is more vertical scratching than the circlip/piston pin coming loose would have generated. 4) Is the piston pin an easy thumb push fit in the piston? (A too tight fit of the pin in the piston is enough to cause seizures with the OEM Art pistons. It is probably the same with the Wiseco.)

G'night all,

Ed

Keep the rubber side down!

-

Bruce Young

- Posts: 493

- Joined: Wed Jul 24, 2013 6:48 am

Re: Day One - New Project

Max, I know you probably have checked these things but Eds, post brings to mind that one needs to put a magnet down in crank area to see if any fragments could be found. Also drain oils and search there as well. As Ed says there could be other more objects that could have come apart to make the damage. The bearings are much tougher metal that could leave deeper scratches. Good luck!!, Max in solving this mystery. We are all pulling for you. Bruce

Bruce Young - HodakaPartsIdaho

Re: Day One - New Project

Quote--I readily admit that I don't KNOW what is causing the seizures, but considering that cylinder, piston, and pin all grow with the heat of operation - I remain unconvinced by the "pin is too long theory".

I remain considerably concerned by the vertical scratches which are quite evident and wide spread in both piston and cylinder . . . so I'll throw another wad of stuff up against the wall to see if anything sticks. 1) Did the cylinder get fully washed after boring to remove machining crumbs? Is the rod big end bearing shedding material(possibly due to #1)? Ditto mag side main bearing? It just seems like there is more vertical scratching than the circlip/piston pin coming loose would have generated. 4) Is the piston pin an easy thumb push fit in the piston? (A too tight fit of the pin in the piston is enough to cause seizures with the OEM Art pistons. It is probably the same with the Wiseco.)

G'night all,

Ed[/quote

A few observations here. I find it strange that a pin that can't be pushed with your thumb can cause a seizure but one one locked in with enough force to push out a clip can't. The piston should be expanding 2X the rate of the pin and as the engine warms should loosen up slightly. But pin length starts out at zero clearance and then grows .002''+ in that space. Try knocking a clip out with a pin and hammer and you will see what forces are required, certainly more than needed to distort a piston. Obviously the clip grooves aren't getting any further apart and that's why it pushes out the clip. As far as the scratches which I explained earlier were caused by the free pin chipping away at the transfer port. One small piece was embedded in the skirt. Magnet searches reveal that the crankcase is clear. One should at least analyze what I'm saying, it's all clear to me.

Max

I remain considerably concerned by the vertical scratches which are quite evident and wide spread in both piston and cylinder . . . so I'll throw another wad of stuff up against the wall to see if anything sticks. 1) Did the cylinder get fully washed after boring to remove machining crumbs? Is the rod big end bearing shedding material(possibly due to #1)? Ditto mag side main bearing? It just seems like there is more vertical scratching than the circlip/piston pin coming loose would have generated. 4) Is the piston pin an easy thumb push fit in the piston? (A too tight fit of the pin in the piston is enough to cause seizures with the OEM Art pistons. It is probably the same with the Wiseco.)

G'night all,

Ed[/quote

A few observations here. I find it strange that a pin that can't be pushed with your thumb can cause a seizure but one one locked in with enough force to push out a clip can't. The piston should be expanding 2X the rate of the pin and as the engine warms should loosen up slightly. But pin length starts out at zero clearance and then grows .002''+ in that space. Try knocking a clip out with a pin and hammer and you will see what forces are required, certainly more than needed to distort a piston. Obviously the clip grooves aren't getting any further apart and that's why it pushes out the clip. As far as the scratches which I explained earlier were caused by the free pin chipping away at the transfer port. One small piece was embedded in the skirt. Magnet searches reveal that the crankcase is clear. One should at least analyze what I'm saying, it's all clear to me.

Max

Who is online

Users browsing this forum: No registered users and 24 guests