Hole in piston

Re: Hole in piston

viewtopic.php?f=1&t=1962&p=13271&hilit= ... ipe#p13234

See if this link works. Discussion and photos on 250SL pipe modification.

See if this link works. Discussion and photos on 250SL pipe modification.

GMc

-

Hodaka250SL

- Posts: 66

- Joined: Mon May 16, 2016 9:12 am

Re: Hole in piston

The link worked just fine. I'll do that after I get the top end rebuilt. And have it broke in. Speaking of braking in what is the proper why to brake in the top end of my 250 after I get it put back together

-

Hodaka250SL

- Posts: 66

- Joined: Mon May 16, 2016 9:12 am

Re: Hole in piston

What is the best way to brake in the new top end

Re: Hole in piston

As with any new air cooled two stroke. Warm it up to full temp but without winding it up. Let it cool to outside temp. Repeat, each time going a little longer. I wouldn't ride it until it has one or two heat/cool cycles. Then work up to full throttle gradually over the course of several short rides, full cool in between each ride. No need to get in a hurry. Break in gradually.

GMc

-

Hodaka250SL

- Posts: 66

- Joined: Mon May 16, 2016 9:12 am

Re: Hole in piston

Finally ordered all the parts to put my bike back together. I can't wait to ride it agine. I love old bikes

Re: Hole in piston

After holing my 250SL piston I discovered that there was more labor involved than rebuilding the top end...

A lot of grit and bits of piston land gathered inside the crankcase and that had to be scraped out. Likewise the main bearings were contaminated and fouled up with debris too.

I saw no alternative than to split the cases and completely clean things up in there:

*Washed and rinsed the crank assembly with soap and water.

*Flushed the main bearings with carb cleaner, compressed air, and vacuum. Had to do this repeatedly until the bearings spun smoothly again.

If this wasn't done I suspect that the bottom end would have had a short life ahead of it.

A lot of grit and bits of piston land gathered inside the crankcase and that had to be scraped out. Likewise the main bearings were contaminated and fouled up with debris too.

I saw no alternative than to split the cases and completely clean things up in there:

*Washed and rinsed the crank assembly with soap and water.

*Flushed the main bearings with carb cleaner, compressed air, and vacuum. Had to do this repeatedly until the bearings spun smoothly again.

If this wasn't done I suspect that the bottom end would have had a short life ahead of it.

-

Hodaka250SL

- Posts: 66

- Joined: Mon May 16, 2016 9:12 am

Re: Hole in piston

I've already done that. I did that the same day I holed my piston in my 250sl

-

Hodaka250SL

- Posts: 66

- Joined: Mon May 16, 2016 9:12 am

Re: Hole in piston

Got the bike back together. Did the leak down test and it dropped 1psi every 3 mins. And it runs a Hole lot better then it did before. And no more running lean. The small hole in the rubber piece between the carb and the intake was the problem.

Re: Hole in piston

Greetings

Glad to see that you solved your air leak/holed piston problem and have helped to keep another 250 SL alive.

However, I would like to point out a potential problem that could possibly give you a bit of grief. According to the owners manual, the front brake cable should be routed through the speedometer mounting plate behind the speedometer. If the cable is routed in front of the speedometer, the cable could loop over the speedometer on compression of the forks and cause the brake to be applied when the forks return to the fully extended position. When this occurs, bad things can happen quickly and ruin a perfectly good day for you and your big Hodaka.

Tom

Glad to see that you solved your air leak/holed piston problem and have helped to keep another 250 SL alive.

However, I would like to point out a potential problem that could possibly give you a bit of grief. According to the owners manual, the front brake cable should be routed through the speedometer mounting plate behind the speedometer. If the cable is routed in front of the speedometer, the cable could loop over the speedometer on compression of the forks and cause the brake to be applied when the forks return to the fully extended position. When this occurs, bad things can happen quickly and ruin a perfectly good day for you and your big Hodaka.

Tom

-

Hodaka250SL

- Posts: 66

- Joined: Mon May 16, 2016 9:12 am

Re: Hole in piston

Thanks for pointing that out to me ill take care of that first thing in the morning

-

Hodaka250SL

- Posts: 66

- Joined: Mon May 16, 2016 9:12 am

Re: Hole in piston

Tom what kinda tires are on ur bike I need to find better ones for my 250sl cuz I have nobbies on mine

Re: Hole in piston

The tires are " IRC trials GP-1 ".

They are good all around performing tires--- in my opinion.

Tom

They are good all around performing tires--- in my opinion.

Tom

Re: Hole in piston

3.00 x 21 front and 4.10 x 18 rear.

Re: Hole in piston

Been re-reading this thread, has a lot of info which may be apropos to the seizure on mine. Got it freed up and looking in the Exh port the piston has metal smeared over the rings on that side. Doing leak test today with borrowed and improvised tester, then disassembly and autopsy.

--Bill

--Bill

Keepin' the Shiny Side up

on a '72 Wombat 94

--Bill

on a '72 Wombat 94

--Bill

Re: Hole in piston

Since you have to take it apart to repair it, the leak down at this point will only be for practice.

GMc

- Bullfrog

- Posts: 2784

- Joined: Mon Jul 22, 2013 4:05 pm

- Location: Oregon, 12 miles from the center of the Hodaka Universe(Athena)

Re: Hole in piston

Although . . . a leak down test after a seizure can be of considerable comfort and peace of mind. If a significant leak is found, we pretty much KNOW what caused the seizure and don't have to lay awake nights wondering which of the myriad of other factors might have caused it. Of course the practice is good . . . cuz the engine ought to be pressure tested after it gets reassembled too.

Ed

Ed

Keep the rubber side down!

Re: Hole in piston

Actually, since the piston is just seized and not ventilated, the leakdown is diagnostic to determine cause. Unless we find more, I don't see going into the bottom end.

The initial pressure loss was measured at One psi per 6 minutes, and I'll do other tests and spray Windex on things and see if we can localiize the losses. -Zero- is the goal.

--Bill

The initial pressure loss was measured at One psi per 6 minutes, and I'll do other tests and spray Windex on things and see if we can localiize the losses. -Zero- is the goal.

--Bill

Keepin' the Shiny Side up

on a '72 Wombat 94

--Bill

on a '72 Wombat 94

--Bill

- Bullfrog

- Posts: 2784

- Joined: Mon Jul 22, 2013 4:05 pm

- Location: Oregon, 12 miles from the center of the Hodaka Universe(Athena)

Re: Hole in piston

Zero is an admirable goal, but perhaps overkill. Pressurize to 6psi - maximum acceptable pressure loss rate is a drop to 5psi in one minute.

Your engine passed the test with a 6 minute time frame to lose that 1psi. So an air leak is not the cause of the seizure.

Ed

Your engine passed the test with a 6 minute time frame to lose that 1psi. So an air leak is not the cause of the seizure.

Ed

Keep the rubber side down!

Re: Hole in piston

Agreed, it passed the test and an airleak is not present, so I'm satisfied. But my Mentor says look and I'll check some other tbings. I have the time, won't be able to take the cylinder, etc, to his shop til Monday.

--Bill

--Bill

Keepin' the Shiny Side up

on a '72 Wombat 94

--Bill

on a '72 Wombat 94

--Bill

Re: Hole in piston

The results of the "extended leak test" :

The _only_ leak found was at the Right Front cylinder stud. "Bubbled" at about 1-2 bubbles/second. How prone is this engine to stripping studs? Is it repairable without splitting the cases? I'll check to see if the stud is stripping or just "loose"-- it may be able to be "corrected" with Loctite or sealant.

And i did find an irregularity in the outer lip of the alternator oil seal-- no oil or air leakage yet, but it's a picky loose end. Should that seal be with the engine assembled?

Disassembly this afternoon.

--Bill

The _only_ leak found was at the Right Front cylinder stud. "Bubbled" at about 1-2 bubbles/second. How prone is this engine to stripping studs? Is it repairable without splitting the cases? I'll check to see if the stud is stripping or just "loose"-- it may be able to be "corrected" with Loctite or sealant.

And i did find an irregularity in the outer lip of the alternator oil seal-- no oil or air leakage yet, but it's a picky loose end. Should that seal be with the engine assembled?

Disassembly this afternoon.

--Bill

Keepin' the Shiny Side up

on a '72 Wombat 94

--Bill

on a '72 Wombat 94

--Bill

Re: Hole in piston

Bill,

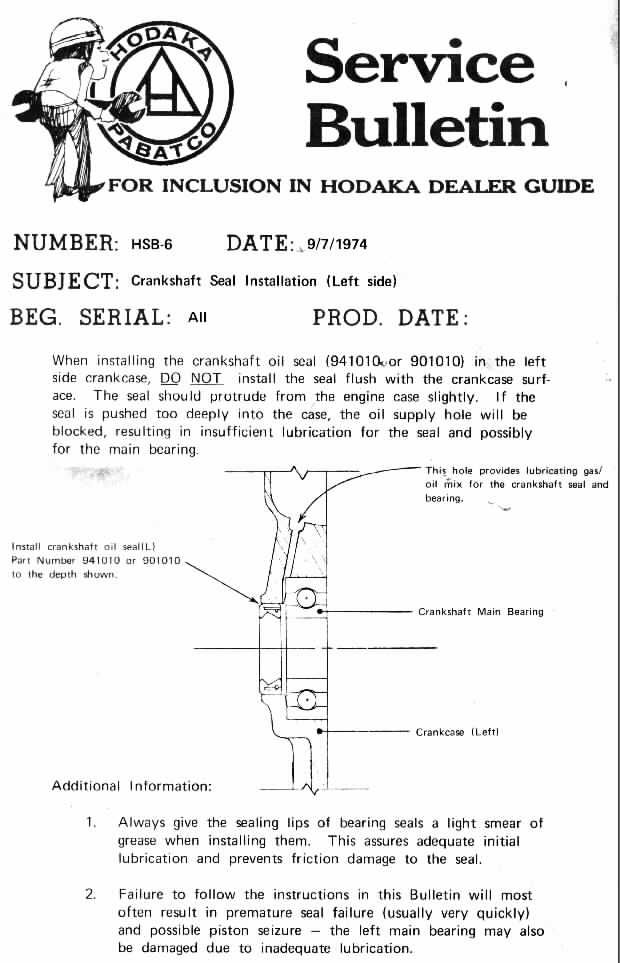

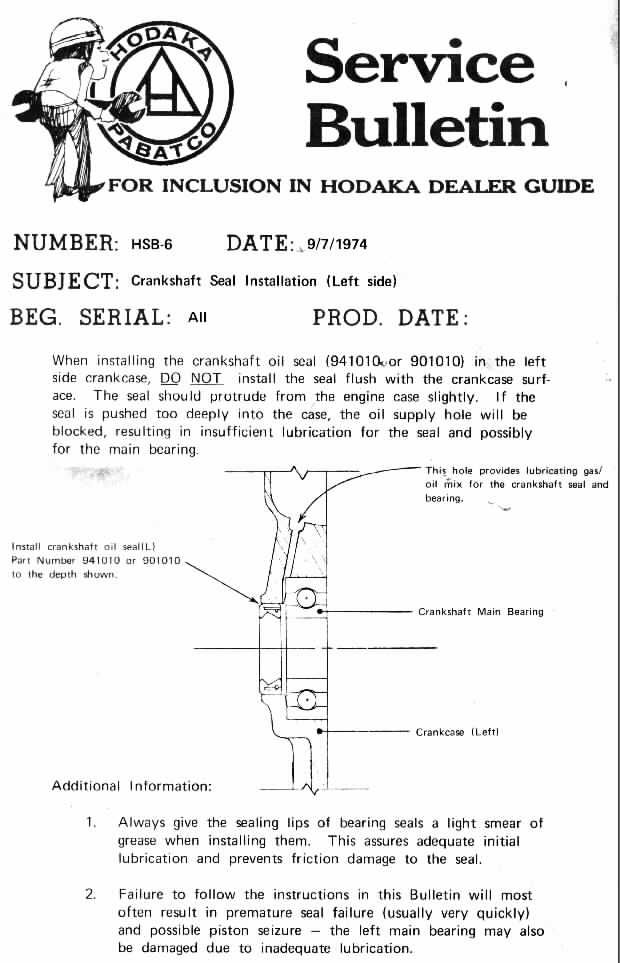

Be careful on how far in you put the seal on the ignition side of the crankshaft. If you push the seal in to far (to try and make it level with the outside of the case) you can sometimes block off the small oil passage from the left side transfer passage to the left side bearing.

Be careful on how far in you put the seal on the ignition side of the crankshaft. If you push the seal in to far (to try and make it level with the outside of the case) you can sometimes block off the small oil passage from the left side transfer passage to the left side bearing.

- Bullfrog

- Posts: 2784

- Joined: Mon Jul 22, 2013 4:05 pm

- Location: Oregon, 12 miles from the center of the Hodaka Universe(Athena)

Re: Hole in piston

See Service Bulletin regarding mag side seal insertion.

Magneto side seal can be replaced with engine in frame.

Regarding the tiny leak at the cylinder stud. It isn't particularly unusual to find a leak at the cylinder studs. A bit of sealant on the threads going into the cases will take care of the problem. While you have the cylinder off, I'd recommend sealing all 4 studs. Since the studs are often installed "dry" - and some of their bores/threads intersect internal areas requiring air tight sealing, leaks can easily happen there. Often times the leak shows up as bubbles at the cylinder head nut washers - a long way from the "real" leak.

Ed

Magneto side seal can be replaced with engine in frame.

Regarding the tiny leak at the cylinder stud. It isn't particularly unusual to find a leak at the cylinder studs. A bit of sealant on the threads going into the cases will take care of the problem. While you have the cylinder off, I'd recommend sealing all 4 studs. Since the studs are often installed "dry" - and some of their bores/threads intersect internal areas requiring air tight sealing, leaks can easily happen there. Often times the leak shows up as bubbles at the cylinder head nut washers - a long way from the "real" leak.

Ed

Keep the rubber side down!

Re: Hole in piston

Good info-- that seal appears to be at a proper depth, I suspect the outer lip got nicked on c'shaft install.

The bubbles at the stud were indeed minor, but account for the 1-psi per 6-7 minutes loss. 'Twas the only leak detected.

I checked the torque on the cylinder nuts and there is no hint that they are stripping.

Got the cyl & piston off, I'm mulling them over.

--Bill

The bubbles at the stud were indeed minor, but account for the 1-psi per 6-7 minutes loss. 'Twas the only leak detected.

I checked the torque on the cylinder nuts and there is no hint that they are stripping.

Got the cyl & piston off, I'm mulling them over.

--Bill

Keepin' the Shiny Side up

on a '72 Wombat 94

--Bill

on a '72 Wombat 94

--Bill

Who is online

Users browsing this forum: No registered users and 3 guests