Page 21 of 24

Re: Day One - New Project

Posted: Wed Sep 21, 2016 4:32 am

by Bullfrog

"Obviously the clip grooves aren't getting any further apart and that's why it pushes out the clip."

Um, the above statement is not correct. ?Everything "grows" with the application of heat EXCEPT the circlip grooves stay rigidly spaced apart with no change? (The pin may be pushing out the clip - but if so, it is not because the pin "grows" and distance between circlip grooves does not "grow".)

Analyzing what is being said goes two ways.

We've all experienced or heard about circlips breaking or coming out -- usually that results from incomplete insertion of the circlip, using the wrong circlip, or damage to the circlip or circlip groove on insertion.

We'll see how it all works out.

Ed

Re: Day One - New Project

Posted: Wed Sep 21, 2016 5:04 am

by hodakamax

Rather than saying everything grows and taking that as an excuse, everyone should play with this test. It's relatively easy to add .003-.004'' width with only a slight turn of the nut. Hardly even enough pressure to push out the clip. The clearance actually increases on the skirt but the width at the pin side quickly fills the bore to zero fit. With the Aluminum piston expanding at twice the rate as the iron cylinder things are going to seize because of the expanding pin and piston sides. We can play with it hot or cold and it's still going to happen. Denial of facts is not going to make this problem go away and I've seen no evidence to the contrary that this is not happening. We don't analyze things two ways but only look at the facts. Of course the next thing to test is whether the grooves do get farther apart or is it enough. With a shorter pin I don't think we'd be having this argument. All interesting and maybe we'll know next week! BTW, I measured clip to pin clearance on a stock Ace 100 which was over .030, a far cry from starting from zero.

Max

Re: Day One - New Project

Posted: Wed Sep 21, 2016 5:27 am

by hodakamax

Another thing to consider and would be quite relative is that the pin is much longer than each pin boss. With the pin bosses not directly in contact they would each grow in width without the clip grooves getting much further apart while the pin grows longer. Lotsa factors here and this could be important. We only need to reduce the piston clearance by less than .001 to initiate seizure.

Max

Re: Day One - New Project

Posted: Wed Sep 21, 2016 7:29 am

by Kels

Max.. the pin can NOT push out a properly seated and installed circlip.. Not gonna happen..

Re: Day One - New Project

Posted: Wed Sep 21, 2016 7:35 am

by ossa95d

Well stated Max and as an engineer I believe there is merit to your statement about the various parts of the piston expanding at different rates and different directions. The skirt expands way less than the crown and the pin bosses would expand independently of each other growing in width. I respectfully submit that it is plausible that the circlip grooves could remain somewhat static in their position while the pin expands. They might even move closer to each other. I agree with Greg that there should be clearance between the ends of the pin and the circlips. I think we all agree with this. A shorter pin and the proper size clips would be indicated. Whether it cures the seizing remains to be seen, but it may.

I do feel that this problem is completely disconnected from the problem you are having sorting out the way the bike runs. Great discourse! I know you will figure it out with the collective help of the group.

Re: Day One - New Project

Posted: Wed Sep 21, 2016 8:31 am

by hodakamax

Hey thanks Ivan! I always respect your opinions. This has been a hard one to figure out. I thought I'd seen everything but perhaps not! I'm behind right now but I'll jump on it next week. Seeing how easy it was to distort the piston and these two things happening simultaneously still has me thinking that the two are related. I think what is happening is the engine is on the verge of seizure after warming up and masks any jetting input with both drag and extra heat. Interesting problem that will be worked out by all. Appreciate your input and sharing your knowledge.

Max

Re: Day One - New Project

Posted: Wed Sep 21, 2016 8:32 am

by dirty_rat

Two things I noticed.

1 - The seizure area of the piston appears to be centered on the intake, right along the intake bridge. IF the pin was distorting the piston to cause the seizure, it seems the seizing would be on the sides of the piston, not the back.

2 - If the piston pin expansion is causing the circlip's to be displaced, then it is moving freely in the piston pin bore and shouldn't be expanding the piston. (As a side note, the piston pin for a Yamaha YSR 50 is the same diameter as a Hodaka 100 pin, but a couple of mm's shorter, you might try one to see if the circlip problem goes away)

As I am not there too see the actual engine and parts, this is just an observation, take it for what it is worth, and good luck with it.

Re: Day One - New Project

Posted: Wed Sep 21, 2016 8:38 am

by DGardner

Harry said to use a pipe from a bultaco trial bike and it is a lot shorter overall, to the one you have. Could this be part of the problem with your jetting? Also looking at your piston it looks like the EX side has got hot...could this also be part of the pipe problem? If the pipe is not scavenging all that heat stays in the engine.

Re: Day One - New Project

Posted: Wed Sep 21, 2016 9:12 am

by hodakamax

Hey Doug and DR, thanks for the input. I think I'll know quite a bit more next week after a tear-down and inspection. The first thing will be checking for for damage and then shortening the pin and installing new proper clips. At least I can get rid of some variables. The exhaust is certainly experimental and can be evaluated then. I'll keep everyone posted.

Max

Re: Day One - New Project

Posted: Wed Sep 21, 2016 7:14 pm

by Bullfrog

Max,

Sounds like a plan - reduce some variables.

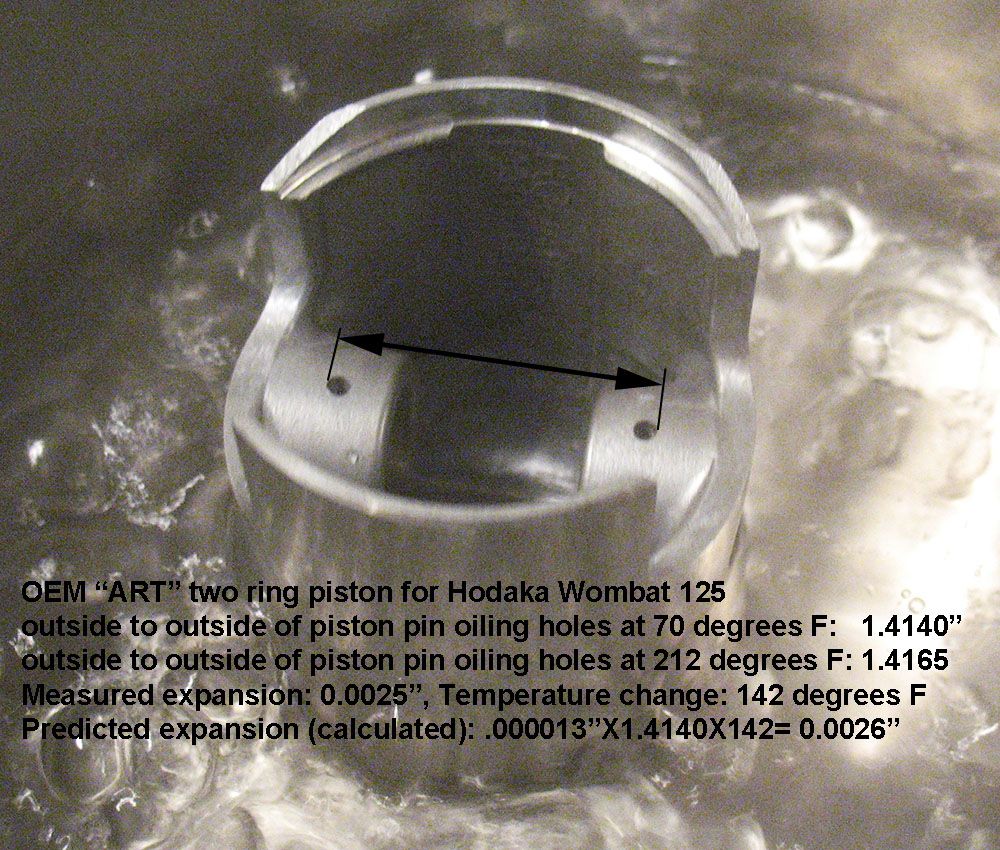

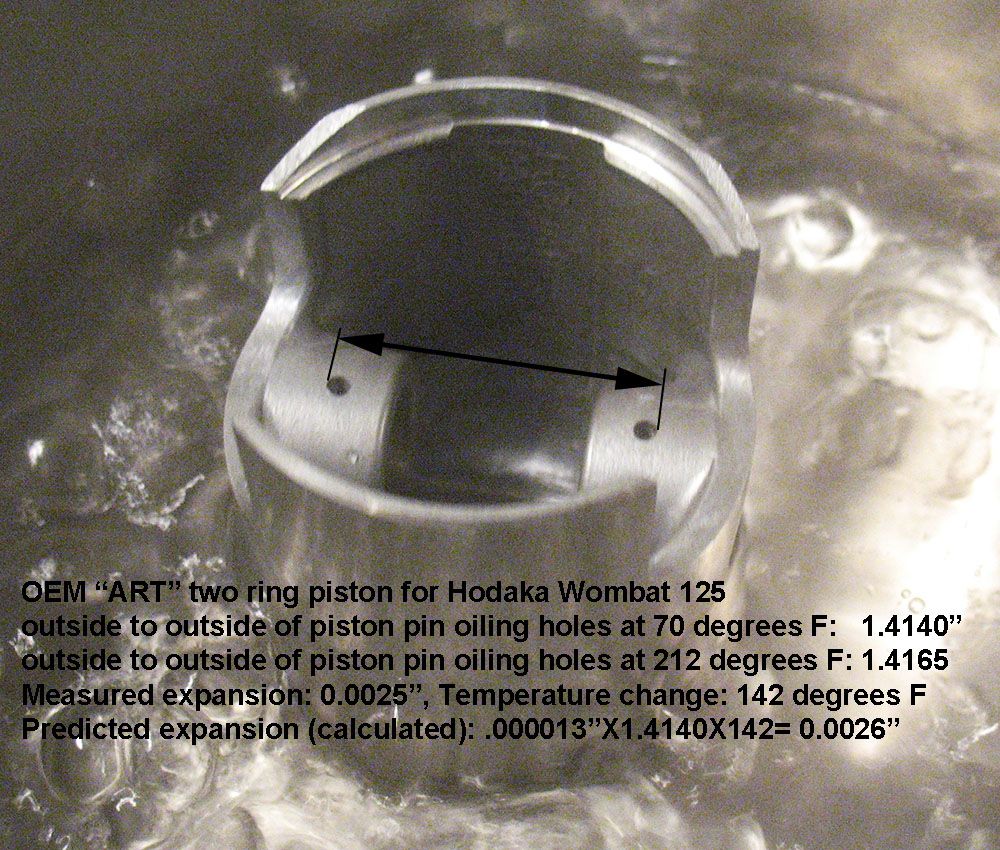

Photo provides some information for your review/analysis.

Ed

Re: Day One - New Project

Posted: Thu Sep 22, 2016 1:39 am

by hodakamax

Ah, science, the way to figure things out! I was wondering how I was going to do that. That also looks like about like my calculated .0025'' and measured .002'' for pin growth. Hmm, now what? I'm still going to shorten the pin next week about .030'' like the stock one I measured, inspect the grooves, and replace the clips just in case I'm missing something. Good work Ed, One step at a time with real data. Thanks!

Maxie

PS--It also might be a good time to increase the piston clearance by about .0005 with a light hone. This would increase the ring gap which I've been trying to avoid, but add to the clearance and remove some of the scratches. It's at about .0025 at the skirts now. Waddaya think?

Re: Day One - New Project

Posted: Thu Sep 22, 2016 3:07 pm

by ossa95d

Well done Ed! That is very helpful information.

Re: Day One - New Project

Posted: Thu Sep 22, 2016 5:36 pm

by Bullfrog

While I don't think shortening the pin will do anything useful other than reduce reciprocating weight by a teensy amount, it won't hurt anything . . . so why not?

I would recommend the most thorough inspection of the circlip grooves you can muster. There is just no way that the proper circlip, fully seated in a properly machined and undamaged groove, can be pushed out by the pin -- at least not without significant damage to the piston. So there is the question of how is it possible that you've had two(?) circlips come adrift????

I'd sure do the light hone - as mentioned before, I really (really) don't like the collection of vertical scratches . . . and a bit more clearance in the iron cylinder would be a good thing.

We'll watch for news.

Ed

PS: The Hodaka 100cc circlips I have are .040" wire, Doug may have measured a 125cc Hodie circlip.

Re: Day One - New Project

Posted: Fri Sep 23, 2016 2:04 am

by ossa95d

While Ed's experiment seems to prove that the expansion of the wrist pin would not dislodge the clip, if the pin was too long to allow the clip to seat properly in the first place the length could still be a factor. Of course .040 wire size clip in a .028 groove could be a problem too. I will say though that Ed's experiment would also seem to debunk the theory that a too tight (more than thumb pressure) fit of the pin in the piston would cause seizures. As Max said the aluminum piston would expand more than the steel pin in effect allowing a more relaxed fit at operating temps. Am I missing something here also?

Re: Day One - New Project

Posted: Fri Sep 23, 2016 5:01 am

by Bullfrog

Except that the thumb-push fit "specification" for OEM ART pistons has proven to be valid over the years - I don't know if the same thumb-push fit is required for Wiseco pistons. Piston pins which are too tight in ART pistons will cause a "four-corner" seizure. I don't have a very good hypothesis as to why - but experience has proven (multiple times) that it is true. (Perhaps, maybe, possibly . . . not enough clearance to allow oil distribution reliably all around the pin?)

I think Doug's post listed .038" (not .028") for the Wiseco circlip wire. And yes ANYTHING which prevents full seating of the circlip in its groove would be a bad thing and must be corrected.

Ed

Re: Day One - New Project

Posted: Fri Sep 23, 2016 5:08 am

by ossa95d

Ed, one certainly cannot argue with the validity of years of experience. I will continue to ream pistons that have a too tight fit as per the thumb push specification. I have never experienced a tight fit with Wiseco. Thanks for sharing your experience with us.

P.S. I went back and checked and you are right that Doug had the Wiseco clip at .038, but he also had the Hodaka clip at .048. I only remembered the .010 difference which certainly would be an issue if the wire sizes are correct.

Re: Day One - New Project

Posted: Fri Sep 23, 2016 5:47 am

by DGardner

Bullfrog wrote:Except that the thumb-push fit "specification" for OEM ART pistons has proven to be valid over the years - I don't know if the same thumb-push fit is required for Wiseco pistons. Piston pins which are too tight in ART pistons will cause a "four-corner" seizure. I don't have a very good hypothesis as to why - but experience has proven (multiple times) that it is true. (Perhaps, maybe, possibly . . . not enough clearance to allow oil distribution reliably all around the pin?)

I think Doug's post listed .038" (not .028") for the Wiseco circlip wire. And yes ANYTHING which prevents full seating of the circlip in its groove would be a bad thing and must be corrected.

Ed

It was a 125 clip.

Re: Day One - New Project

Posted: Fri Sep 23, 2016 2:47 pm

by tvrc18

I have some Bultaco's and you must heat the piston to get the pin in so a tight pin should not be a problem but most Jap bikes are the thumb push style. Most likely the clips did not seat properly because wrong clips or? I have never had a clip come out with over 50 years of riding, racing.

Terry

Re: Day One - New Project

Posted: Sat Sep 24, 2016 2:32 am

by hodakamax

Yay, It's time for the annual Dawg Days Car and Bike Show today! My wife and I are headed out this morning with two Hodakas and a Yamaha XS-650, all vintage including Us! Little do they know that the Day One Project is not running and I ain't tellin'.

The Hodakas are in the Tundra and the Yamaha seemed eager by firing up having not been started since the last show a year ago. Looks like a great day weather wise and we're off! A report soon!

Max and Eweleen

Re: Day One - New Project

Posted: Sat Sep 24, 2016 3:27 am

by ossa95d

Have a great time at the show Max! We'll back you up on your secret about the Day One Project... Like many concept vehicles, tecnically it does run, just not up to it's designer's expectations...

Re: Day One - New Project

Posted: Sat Sep 24, 2016 9:42 am

by hodakamax

Wow! Just got back with Best of Show/Motorcycle! Eweleen even won a door prize gift certificate to her favorite Girley Shop in town. Not a bad day overall. We also had fun talking to all the people who owned (or their Uncle did) a Hodaka or Yamaha XS-650 in the past which was probably the funnest part of all. The XS-650 also seemed happy on its once a year 18 mile ride round trip to the show (but not to losing to the Day One project on its first time out.)

Hey Ivan, Still no one found out that it didn't actually run but it also prevented me from entering the burn-out contest, probably for the better.

Anyway, reporting on a good adventure!

Max and Eweleen (with our replica Good's Cycle Shop shirts from the 60's.)

Re: Day One - New Project

Posted: Sat Sep 24, 2016 10:23 am

by matt glascock

Congratulations Maxie!! I've followed the Day One build from - well - day one. Innovative, well engineered, and totally cool. Did you have a "before" picture hanging on the bike? Well done!!

Re: Day One - New Project

Posted: Sun Sep 25, 2016 2:16 am

by hodakamax

I now see that one of my crazy friends has "photo-bombed" Eweleen and I, is there no safe place from these people?

Max and Eweleen

Re: Day One - New Project

Posted: Thu Sep 29, 2016 3:43 am

by hodakamax

Well Gang, I thought I should report in in case someone thinks I've come up missing. The weather is perfect here and it's time to act on something I've been putting off because of the Day One Project namely fixing a few exterior house problems before winter sets in. Greg (AZ) has been in touch and mentioned a few things of note. We are both starting to think that it just needs more clearance with an iron cylinder and a forged aluminum piston which has a greater expansion rate than a cast one. While on the ladder I've also been thinking about my experimental exhaust and stinger. I'll test it without the stinger/muffler soon to see if it makes a difference. Even motorcycles with problems are more fun than replacing siding and the related drama. Almost done, back soon!

Maxie

Re: Day One - New Project

Posted: Fri Oct 07, 2016 3:21 am

by hodakamax

Reporting in after having to do a necessary house repair before it rained. Mission accomplished and just in time. Just emptied the rain gauge a few minutes ago for a final total of 8'' in two days. All is well and back to the project. New clips on the way, clearance upped to .003 with a slight hone which removed most of the cylinder scratches. After doing a few quick tests by heating the piston I find that the forged Wiseco piston expands even more than Ed's test which further shows that there is probably no benefit to shortening the pin. The Hodaka clip was still in place on the teardown and no damage is evident in the groove. Either a fluke or I didn't have the clip properly seated in the first assembly. On to reassembly and being suspicious of my experimental exhaust. Between losing a clip (which has never happened to me in my career), too tight of clearances, and an all new set-up, it had me a little befuddled, I guess is the word, but lessons learned and back to work!

Reporting!

Maxie